Mechanical Systems Design

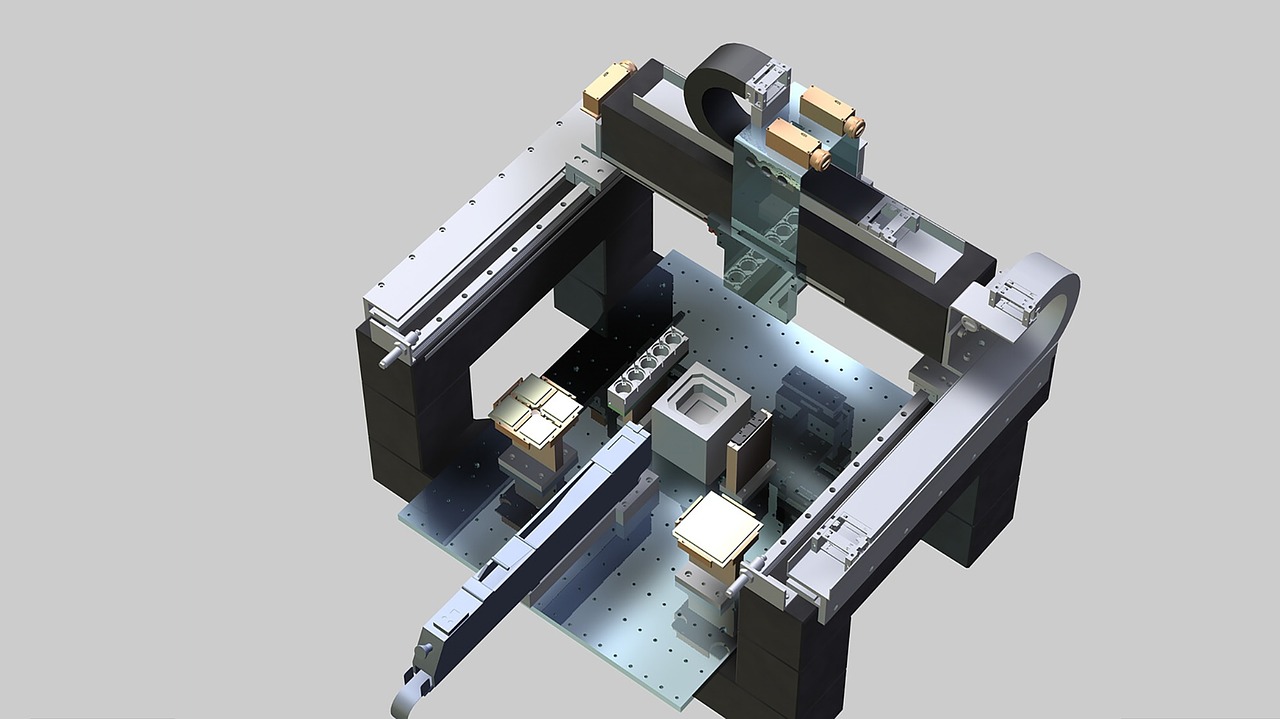

The Mechanical Systems Design Division focuses on the design and development of hardware and the systems that they are built from. Solutions can range from designing a single custom component, a system of custom machined components, or combining many off-the-shelf components with custom components to form a complex system. We can assist with the design and development of a single component that integrates into a machine or system or we can develop a complete automated machine. The Mechanical Systems Division is really where all of the different disciplines of EES come together. We leverage our diverse backgrounds to create a complete solution that meets your needs. It may require some programming or proprietary software development that works in conjunction machined components that we have designed.

Whether your component involves optics or not we are the design firm to handle it. We will work closely with you to fully understand your needs and then design a product that quickly and efficiently addresses those issues. In many cases we can manufacture the component as well, please see our Machining and Manufacturing page.

Every component we design takes into account Design For Manufacture (DFM). Our manufacturing experience helps us to provide better engineered components that are ready to be produced. This reduces engineering time, machining and production time, which makes the entire process more efficient. The Mechanical Systems Design team is made up of hands-on engineers. We have all assembled things, repaired things, and all of us enjoy getting our hands dirty on automotive projects in our spare time. Our hands-on experience is evident in our work. Every component EES designs is made with ALL users in mind; this means the machinist, assembly worker, technician and scientist who will ultimately be using it. We are happy to talk with the end users, ask how things went, and incorporate that information for future improvements. All too often we have seen first-hand that something is designed, manufactured and released without ever talking to the person who will be using it. We seek to change this. Our iterative design process leads to the best possible parts for every situation.

EES has years of experience in the optics industry and the design of all components to support that field. We have thin film coating experience (IBS and APS) and have designed and personally used the tools and fixtures associated with those processes. We have high vacuum experience (10^-8 torr) and have designed several assemblies and components for this type of environment. We have optical fabrication experience and have supported an optical fabrication area with all of the tools required. We have built and modified machines for custom applications. If it involves optics, you name it and we have done it. We specialize in the design of coating deposition tooling, optical cleaning and inspection tooling, optics assembly tooling and shaping, grinding, polishing, and fabrication tooling. There are subtle differences that separate optical components from standard mechanical components. If you have worked with them you understand this. We also offer consultation, calibration and other engineering work related to the optics field. We have experience modeling thin film coatings, and calibrating deposition machines. This includes rate prediction, uniformity analysis and control, and repeatability improvements. We have numerical modeling skills (typically using Matlab), have a deep understanding of the super-polishing process and the quantification of measurements related to sub-angstrom surface roughness.

Whether your component involves optics or not we are the design firm to handle it. We will work closely with you to fully understand your needs and then design a product that quickly and efficiently addresses those issues. In many cases we can manufacture the component as well.