Fabrication Tools

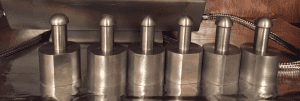

EES has experience supporting all aspects of the optics fabrication process including blocking, grinding, and polishing machine upgrade and maintenance. We know what it takes to fabricate glass and this allows us to focus on the critical aspects of the tooling so that our customers can do their job more efficiently. We have fabricated many parts for super-polished optics (0.5 angstrom or better RMS roughness) and we know the importance of a good tool that is free of burs that will not contaminate your polishing slurry.

We specialize in making the standard “angle tools” that are common to the optics industry (shown below). We can make a variety of different sizes and routinely hit tolerances of +/-2 arcmins (0.033 degrees). Row to row height error from bottom surface is usually within +/-0.0005”. We can make the angle polishing tools from aluminum or steel. We stock many different material sizes and can stock customer blanks so that in emergency situations we can deliver a tool in 24 hours.

EES also makes radius tools used for grinding as well as polishing with pitch. These can be concave or convex spherical shapes or we can do other surface profiles such as cylindrical, or aspherical by utilizing our 3D milling capabilities. These can be made from aluminum or steel and radii can be as small as 10mm or less.

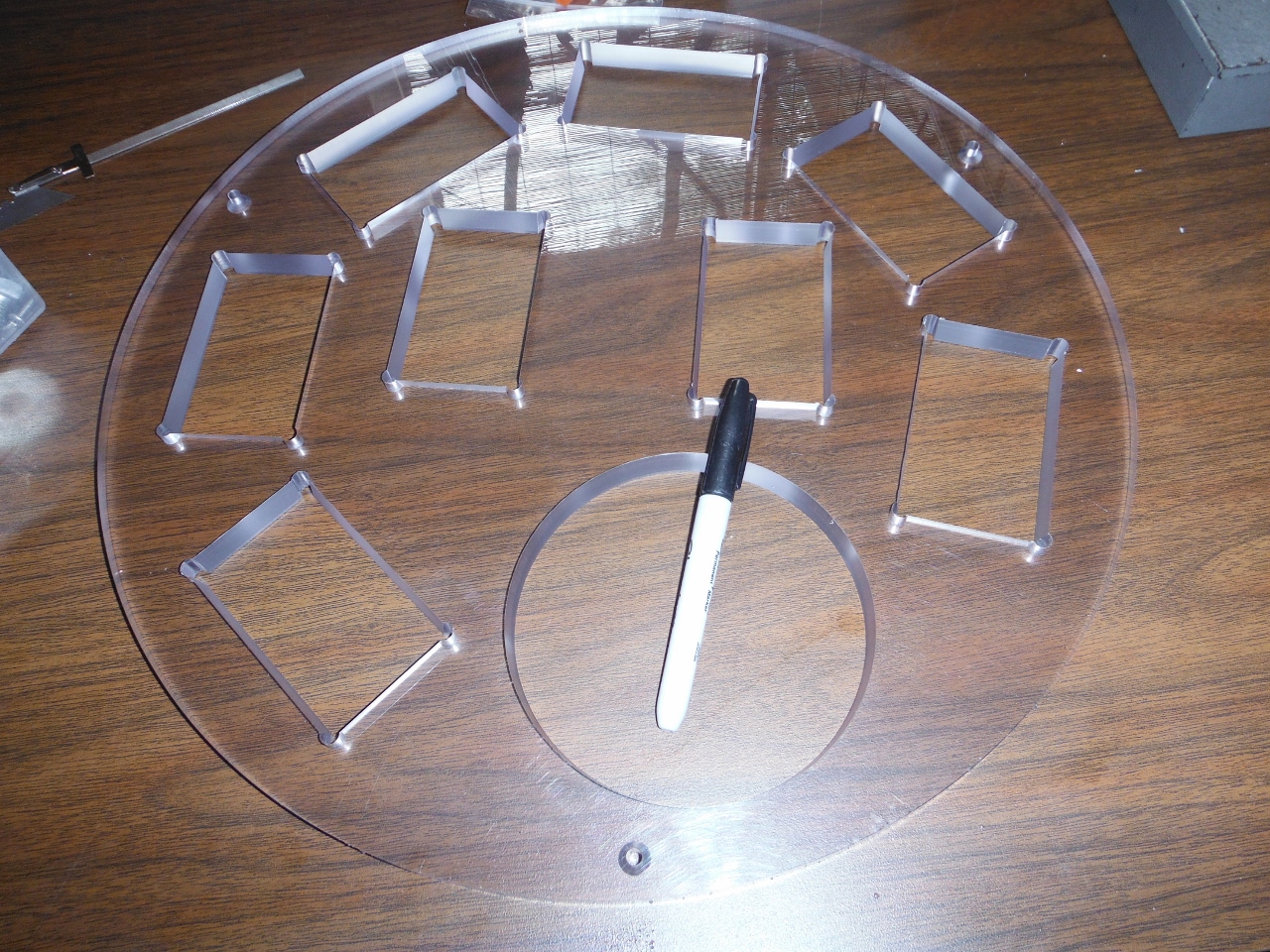

Carriers: EES offers its own carrier that is compatible with the common gear style double side polishing machines. It most polishing machines that take the common 66 tooth carrier designs. Ours is an improvement over what is out there because ours has only a 1/8” hole in the center leaving more real estate for optics on the carrier. We can sell them as blank units or with machined holes for your particular size of optics. Please contact us for more details.

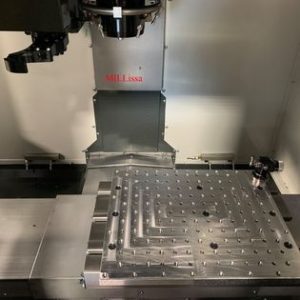

We know that many times a machine will need a modification for a specific job or to be better matched to a certain process and we excel at the design, manufacture and implementation of machine modifications. We can help you map out a modification and gather requirements, design the mod using CAD software, machine the necessary parts and then install it on your machine. Many machines also need replacement parts or routine maintenance and we can help with that as well. We can design a part off of the broken original one and even add improvements before making you a replacement. We can also do the installation as an option.