Assemblies

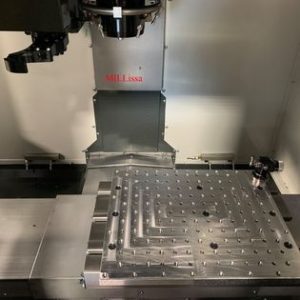

EES’s real value is in combining all of our skills into a single solution. This single solution can benefit from our optics background, our design capabilities, our manufacturing experience, and our software programming abilities. EES is the one stop shop from inception to release. You will only have one place to call to check the status of each step. It means that EES is accountable for all aspects of a project and leads to easy clear communication. This saves both time and cost and leads to a better product for the end user.

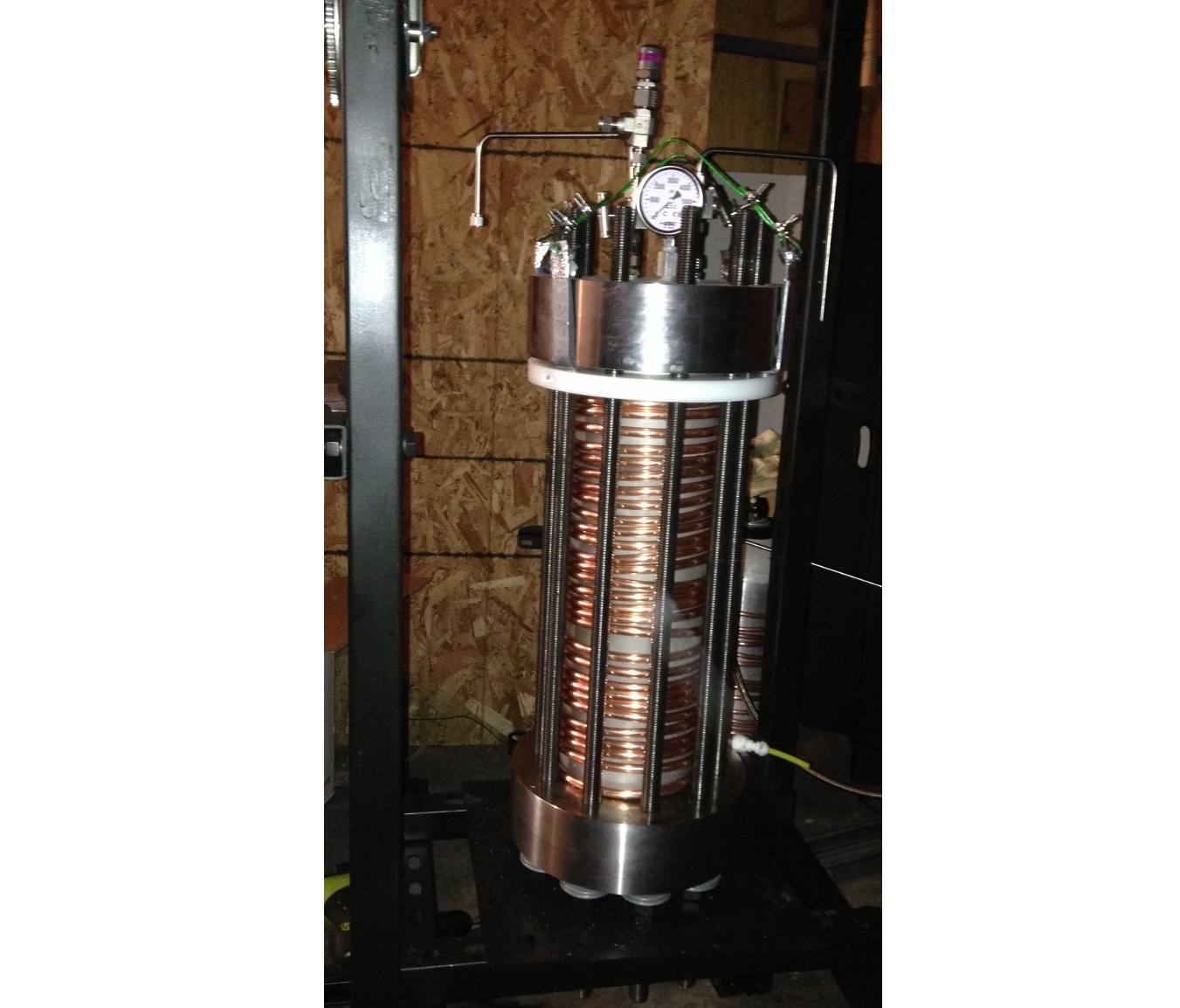

We can design small subsystems such as light sources, vacuum process heaters, and metrology fixtures. We can also design larger systems like polishing machines and vacuum coating assemblies and chamber upgrades. We can also do modifications or retro fits to existing machines, such as converting an old cylindrical polisher into an outer diameter polishing machine. We can also design machines that streamline processes, such as a small lathe that accepts edging spindles. This allows an edging tool to be faced on the spindle before each use. This helps to square up the parts and means that the tool does not have to come off the spindle from the beginning to the end of the process.

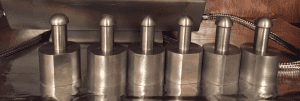

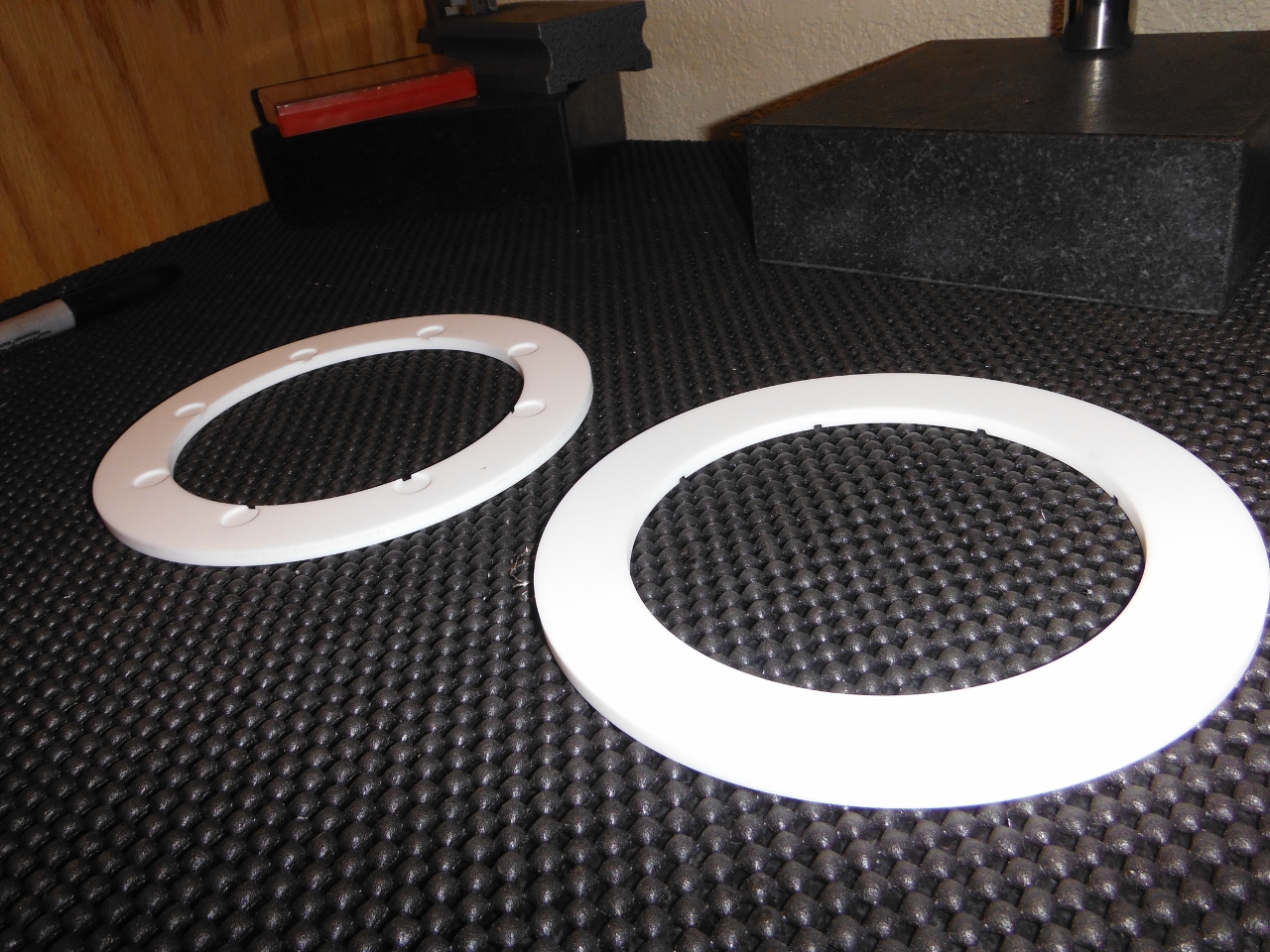

We have done vacuum chamber retro-fits and upgrades and are familiar with the requirements of a high vacuum environment. We can design coating fixtures such as planetary assemblies, and single rotation fixtures. If you have a difficult part that you think will need a dedicated fixture to coat just let us know. We are comfortable machining most of the vacuum safe materials such as aluminum, #304 stainless steel, Macor Ceramic, PEEK, Teflon, Delrin etc. We can often make recommendations on materials based on things like outgassing, thermal expansion, and structural integrity.

All of the assemblies we make can be delivered ready to use and we can include spare parts kits as well. Precision alignment is available where applicable, assemblies can be aligned within 0.001” or better. We offer vacuum cleaning of assemblies if needed. We can travel to your facility to gather requirements and measurements and even assist in the installation upon completion. EES supports the products we make so future maintenance and upgrades will go smoothly due to our one-stop-shop foundation.

If you are looking for a custom assembly please give us a call and see what we can do for you.